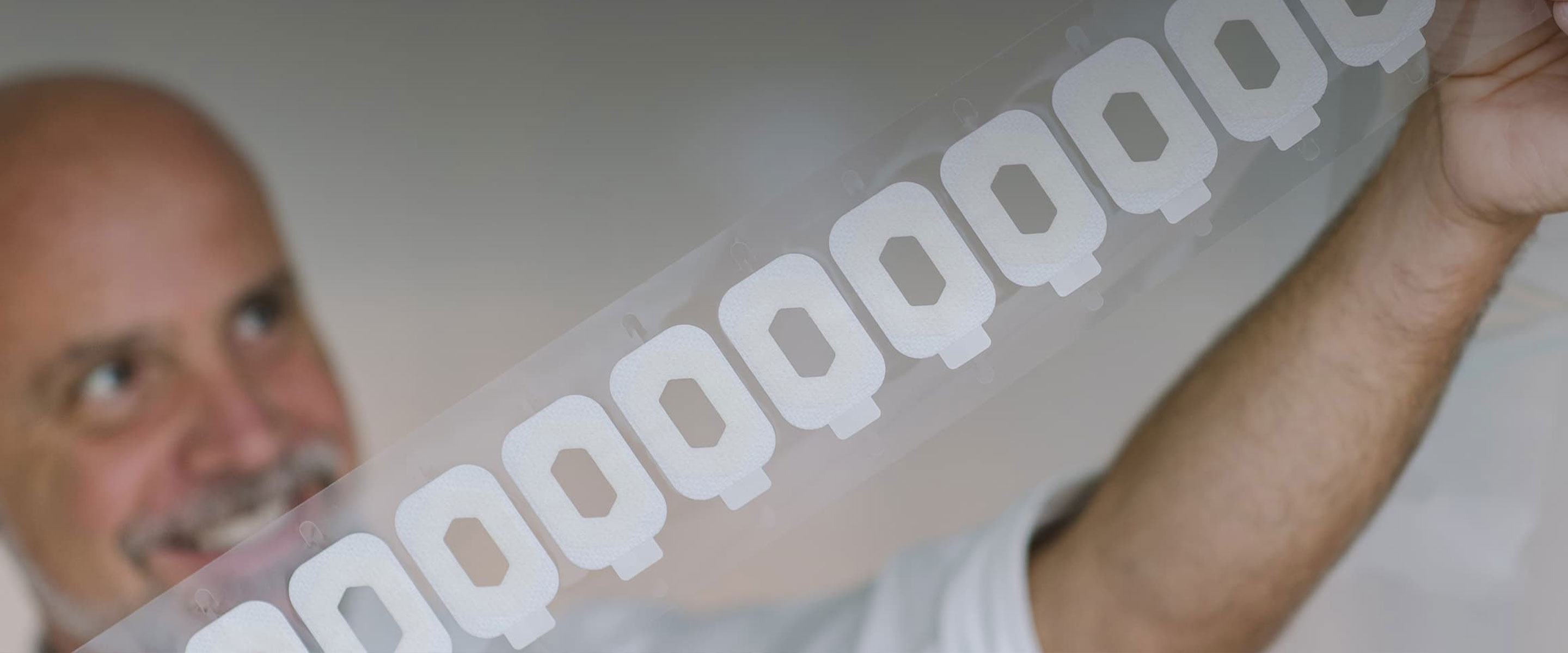

Die Cut Components

Linxens Healthcare is a contract manufacturer of precision die cut and multi layer laminated components for the demanding manufacturing industry.

With a great deal of experience and state of the art machines, technically challenging components can be manufactured. Linxens partners with you through your design process to develop and manufacture products that scale seamlessly from prototype to high-volume production.

Die Cut Components

Exact die cut adhesive parts are an efficient solution for assembly of parts, material stacking and/or sealing.

Explode

Click on each dot to learn more.